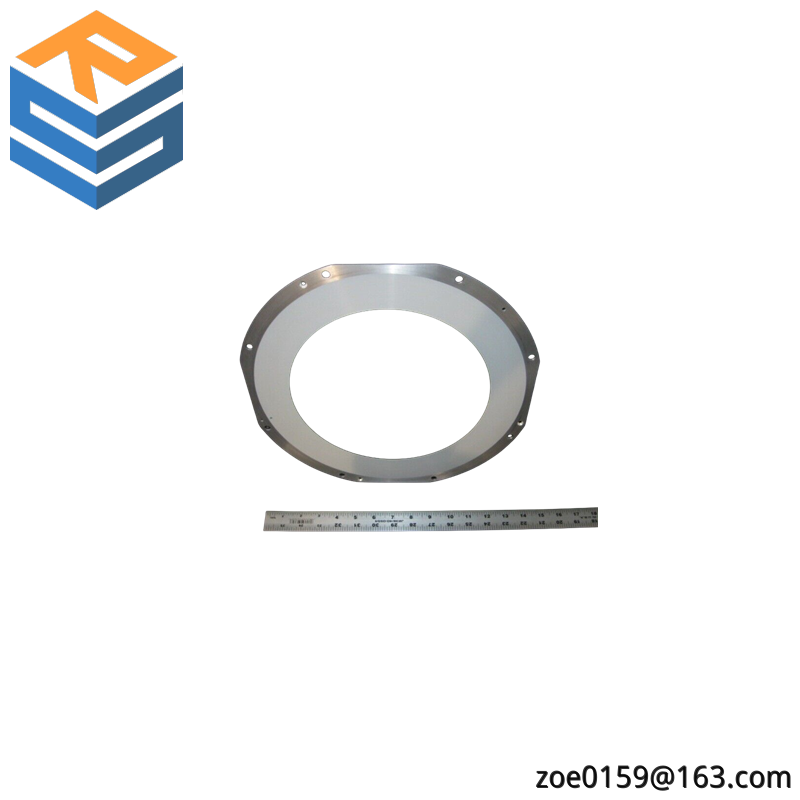

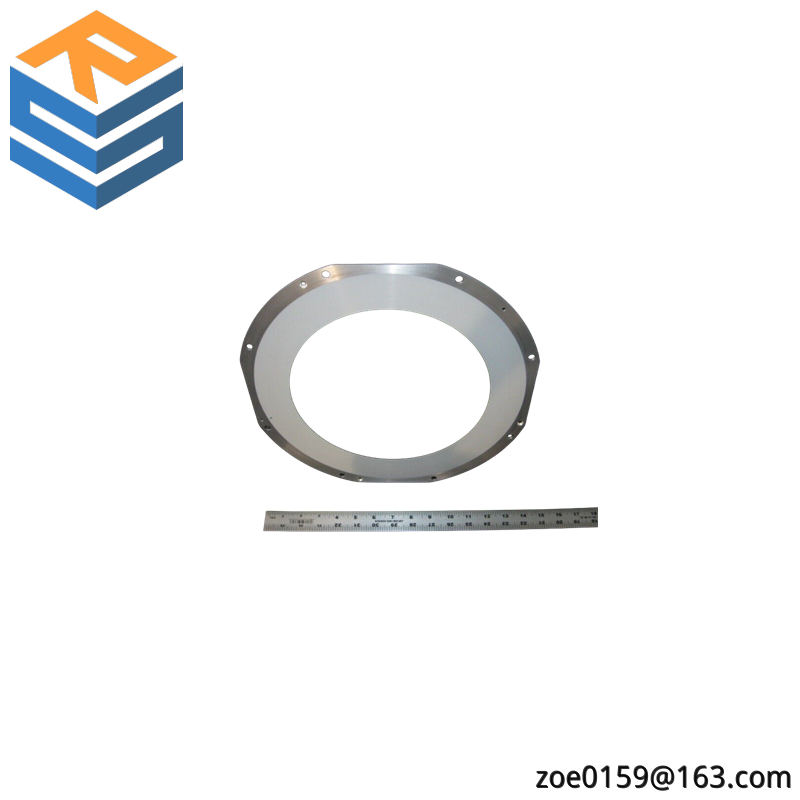

Model Number:0020-33666

Manufacturing Process Compatibility:Supports wafer sizes from 100mm to 300mm

Precision Rating:±0.01 micron accuracy

Operating Temperature Range:-20°C to 45°C

Power Consumption:1500W at maximum output

Material Handling Capacity:Up to 50 wafers per hour

Energy Efficiency Ratio:20% reduction in energy consumption compared to previous models

Engineered for cutting-edge semiconductor fabrication, the Applied Materials 0020-33666 New stands at the forefront of industry standards, boasting state-of-the-art technology that streamlines wafer processing.

Featuring a robust yet compact design, this module optimizes space usage without compromising on performance, making it ideal for both high-volume production lines and compact R&D environments.

With its advanced temperature control system, the unit maintains precise process conditions, ensuring consistent quality across all wafers processed. The low vacuum level facilitates efficient etching and deposition processes, minimizing material waste and maximizing yield.

Equipped with a sophisticated cooling mechanism, the 0020-33666 New ensures rapid temperature adjustments, reducing cycle times and increasing throughput without overheating sensitive components.

The module’s compatibility with a wide range of semiconductor materials allows for flexibility in handling diverse applications, from silicon to III-V compounds, supporting innovation in the semiconductor industry.

Offering full automation, the system reduces human error, enhances productivity, and enables real-time monitoring and adjustment of processes through integrated software solutions, ensuring optimal performance and minimizing downtime.

There are no reviews yet.